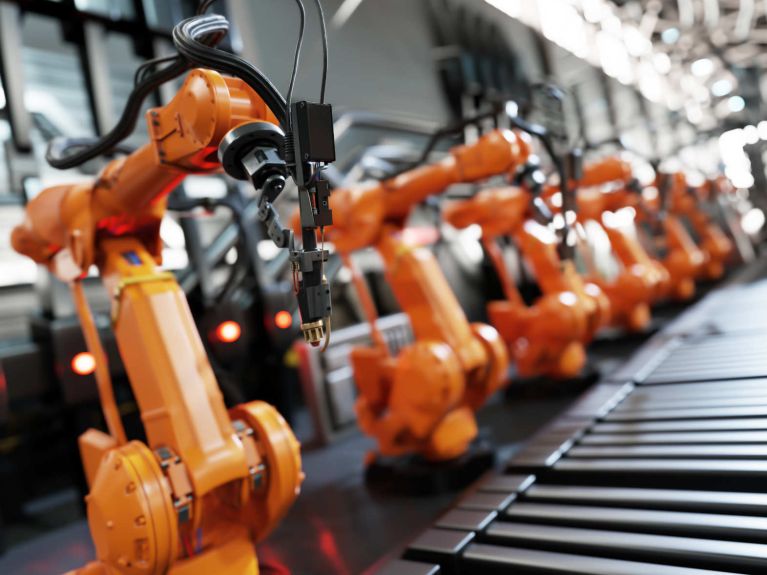

Smart factories in German industry

Germany is a global pioneer when it comes to using artificial intelligence in industrial manufacturing.

Artificial Intelligence, or AI, is fundamentally changing the world of work. Many experts expect revolutionary upheavals similar to those caused by the Industrial Revolution in the 19th Century. According to the German Federal Ministry of Labour and Social Affairs, by 2035 there will no longer be any jobs at all where AI is not relevant. This includes jobs where you would not expect to say that nowadays, the ministry says. Estimates by the consultancy and audit firm PwC suggest that AI could contribute up to 15.7 trillion US dollars to the global economy by 2030.

How innovative is Germany in the field of AI?

Most of the headlines are being generated by so-called generative AI models such as ChatGPT, which are able to produce text, images, videos and computer code independently. However, the innovative power of these developments will ultimately depend on how AI is put to use. This will not just be in consumer applications, but above all in industrial manufacturing. Germany has been an international leader for many years in terms of registering AI patents. The term “Industry 4.0” was coined at the Hannover Trade Fair in Germany in 2011 to describe the innovative use of digital technologies. Now the concept is recognised around the world for the development of so-called “smart factories” where manufacturing processes are monitored and measured by large numbers of digital sensors.

Dieses YouTube-Video kann in einem neuen Tab abgespielt werden

YouTube öffnenThird party content

We use YouTube to embed content that may collect data about your activity. Please review the details and accept the service to see this content.

Open consent formHow are German businesses using AI?

AI can trawl through vast quantities of data to identify trends which might be very difficult or even impossible for a human to spot. AI can use machine learning to analyse images and videos recorded by cameras to spot patterns and anomalies which could suggest potential errors. The aim is to spot and prevent errors early on. Engineers call this “predictive maintenance”. Using AI-based image recognition now also allows robots to act more independently, such as handling certain predetermined parts. The Heidelberg Aleph Alpha AI startup and the IT service provider Hewlett Packard Enterprise recently announced they were developing an AI assistant specifically for factory staff. Much like a specialist service technician, the assistant helps workers complete complex tasks.