Miss Hydrogen

Ulrike Beyer works at the Fraunhofer Institute for Machine Tools and Forming Technology IWU in Chemnitz, where she wants to produce hydrogen systems of the future that are easy-to-use, cheap and robust.

People who want to contribute to the energy transformation in response to the climate crisis: We introduce individuals whose ideals and commitment are driving the expansion of renewable energy in Germany and around the world.

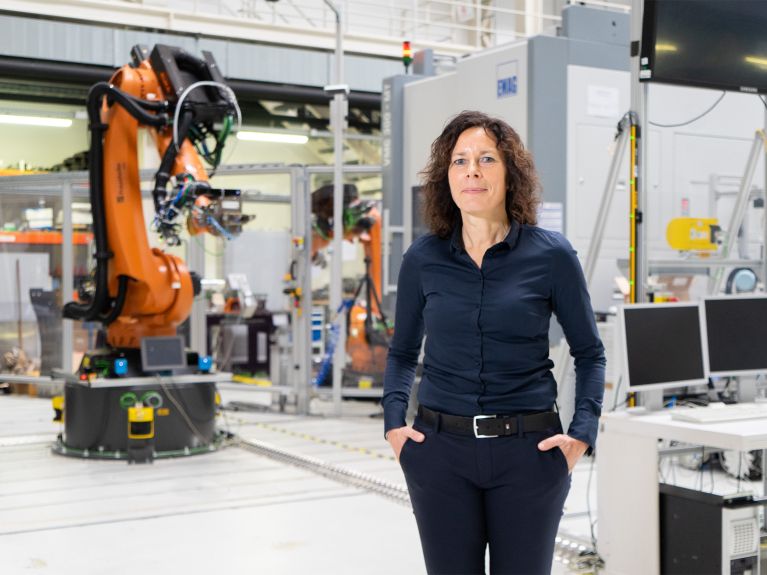

“I always say making the energy transition a success will require many different solutions and elements. There are many different paths to take, but we all share the same green goal,” explains Ulrike Beyer. While she speaks to us, the engineer is holding a metallic bipolar plate, which has just been rolled between two rotating rollers. Ulrike Beyer is head of Referenzfabrik.H2 at the Fraunhofer Institute for Machine Tools and Forming Technology IWU in Chemnitz. She is standing in a production facility, where she is surrounded by 3-metre high mechanical presses, industrial 3D printers, rollers and heavy-duty robots. Her aim is to produce the hydrogen systems of the future which are climate-neutral, cheap and robust.

Hydrogen is a close friend of renewable energy.

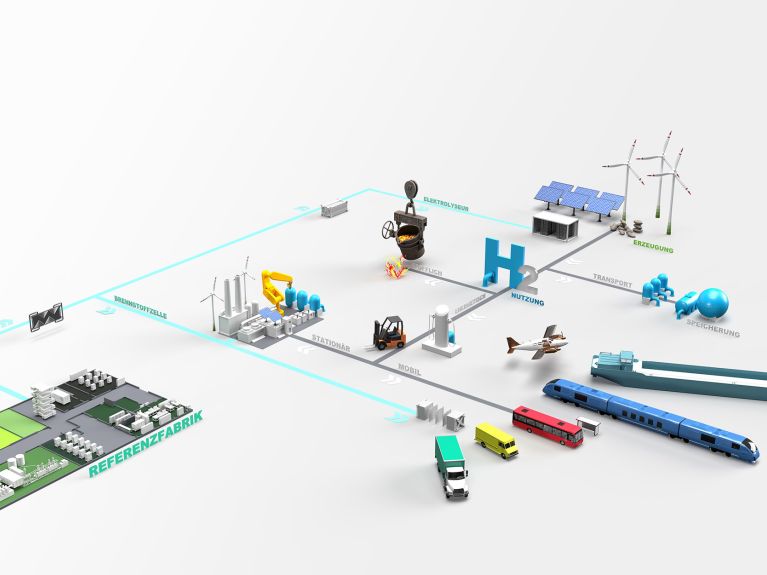

The energy transition is well underway, and green hydrogen is becoming more and more important. Hydrogen is a versatile source of energy and is considered to be a key element in efforts to reduce carbon emissions. So how is green hydrogen produced and how can it be used? Dr Beyer trained as an engineer and has a few ideas on the subject. “You could say hydrogen is a good friend of renewable energy,” she says, adding that hydrogen can make it possible to store and transport renewable energy. “Think of it like cheese, which makes it possible to store fresh milk.” Beyer says there are areas in Germany and around the world which are ideal for generating renewable energy using sun, wind and water. However, these regions do not often coincide with areas where demand for energy is highest. “Hydrogen lets us take energy to where we need it.”

____________

What does “green hydrogen” mean?

- From green and blue to grey and turquoise, although hydrogen is a colourless gas, colours are used to indicated how it is produced.

- Green hydrogen is produced through the electrolysis of water, using power generated from renewable sources. This makes green hydrogen carbon-free.

- An electrolyser is a device in which a chemical reaction is produced with the aid of an electric current.

- Hydrogen is converted back into water in a fuel cell, where it is combined with oxygen, thereby generating energy.

- Bipolar plates are stacked up, forming the heart of a fuel cell and an electrolyser.

____________

Beyer and her colleagues at Fraunhofer IWU want to take the manufacture of hydrogen systems to a new level of mass production. The German Federal Government is supporting the project through the National Hydrogen Strategy. It aims to embed the production and use of hydrogen systems as cornerstones of the German economy, thereby promoting the decarbonisation of society and the economy.

Dieses YouTube-Video kann in einem neuen Tab abgespielt werden

YouTube öffnenThird party content

We use YouTube to embed content that may collect data about your activity. Please review the details and accept the service to see this content.

Open consent formOne of the decisive steps has been the development of new production techniques for bipolar plates, which are a core component of fuel cells. It remains the case that bipolar plates are not in large-scale industrial production. “Right now they are still being made on a cottage-industry basis. That makes the fuel cells expensive and prevents them from finding wider use such as in vehicles or buildings,” explains Beyer. She is standing next to a fuel cell system and shows us where the stake of bipolar plates will be installed. “We can claim our first successes here in reducing costs,” she says. The team at Fraunhofer IWU are also producing the plates through quicker and more efficient processes such as plate stamping.

Referenzfabrik.H2: a construction kit for industry

The development of hydrogen systems which are suitable for use on a mass scale could not only reduce carbon emissions but also become a sustainable and future-oriented business area for Germany as a manufacturing location and many parts of the world. This is what the Referenzfabrik.H2 project is aiming to achieve. Working with partners in industry, new technologies, materials and testing methods are being developed to allow the production to be scaled up and to make it possible to build supply chain networks. “Here at Referenzfabrik.H2 we want to develop the technological elements and combine them virtually. Our aim is to provide orientation for the mass production of hydrogen systems,” Beyer says. The plan is for Referenzfabrik.H2 to be a point of contact and advice for business, from large carmakers to industrial SMEs. Specialists and managers are supported with the combined expertise of the Fraunhofer Institutes.

International partnerships to promote acceptance of green hydrogen

Beyer believes international partnerships are essential in the field of green hydrogen. It is not just in Germany, she says, where intensive research has been taking place for years into the possibilities of hydrogen production. “The more we share our experience and data, the quicker we’ll find solutions,” Beyer says. To this end, the Federal Ministry for the Environment, Nature Conservation (BMUV) is funding two large-scale IWU projects in Namibia and South Africa. The aim is for the exchanges to lead to greater acceptance of the use of hydrogen in these countries, and to provide long-term stability for energy supplies. “For example, we are exhibiting model fuel cells and electrolysers in Namibia and talking to researchers there about the specific needs of their country, along with the many opportunities provided by hydrogen,” explains Mary Esther Akademischer, group leader and project coordinator for the cooperation projects, Hydrogen & Oxygen Biotop (HygO) in Namibia and Hydrogen Tryout Areal (HyTrA) in South Africa.

It is precisely those many opportunities which drive Ulrike Beyer. “A few years ago, Fraunhofer was looking for ‘Mr or Miss Hydrogen – someone to pick up the issue and move it forwards. I didn’t give it a second thought,” says Beyer. “Nowadays many technological developments are so advanced that, as a researcher, there is little you can do to readjust them.” Hydrogen, however, is still sapling, Beyer says, which has only just been planted. “There is still so much you can do to help shape its development. You can mould processes and find new ways forwards. That’s what drives me.”